The specialised expertise of Miko Marine has been called-in for the design and manufacture of sea water inlet closures on the N’Kossa Floating Production Unit working in the Congo Basin. Operated by Total Exploration & Production Congo, a subsidiary of TotalEnergies, the 30,000-tonne N’Kossa concrete floating structure sits in 170 m of water and is linked to two drilling platforms 3,200 m apart.

Miko’s experience of the precise manufacture of many types of hull closures has enabled it to respond promptly to the needs of Total Exploration. The contract specified a requirement for precisely made closures that could be positioned and sealed by divers. This resulted in one 24-inch blank that was delivered in June and one 40-inch sea intended for delivery in November.

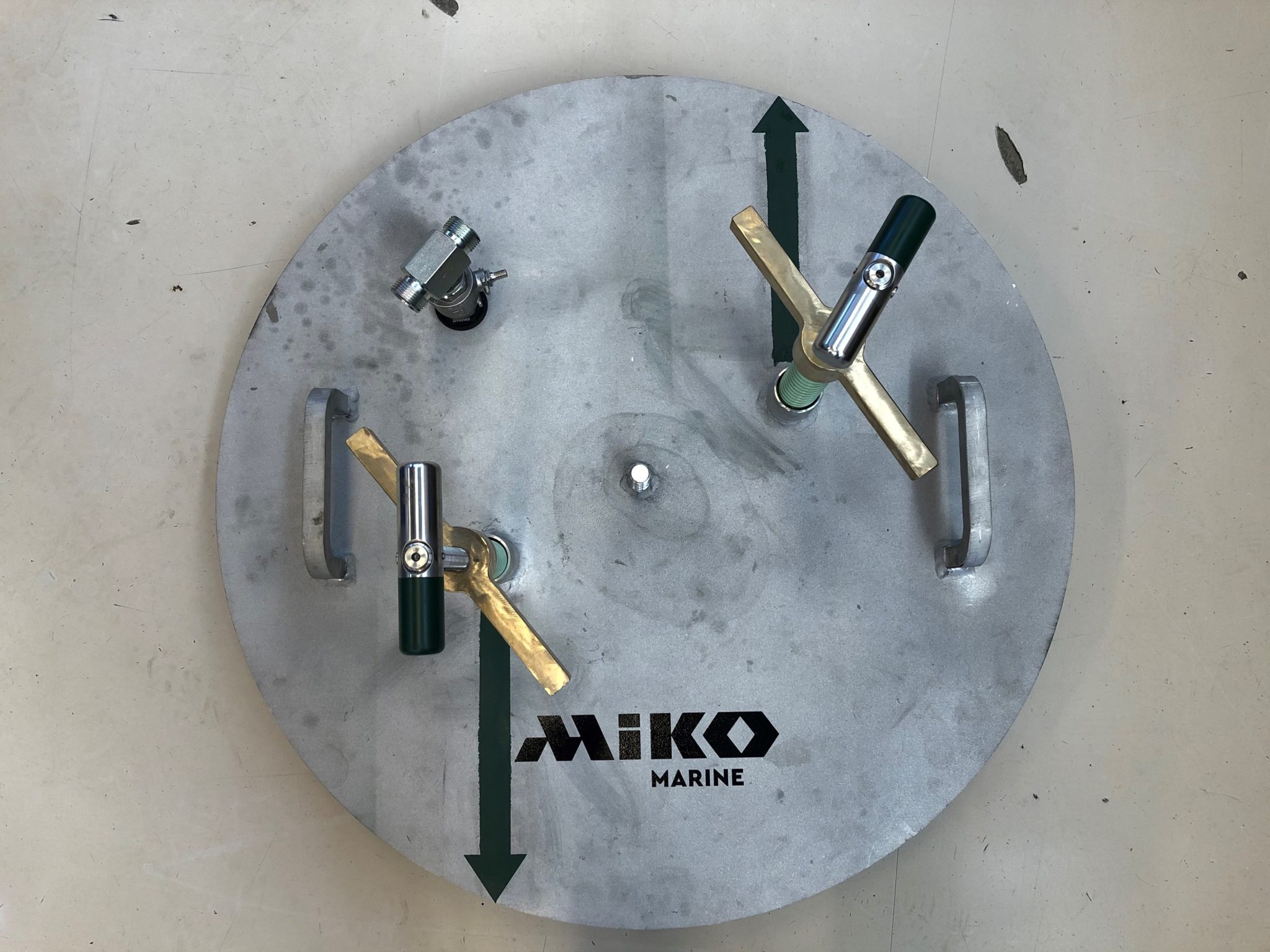

The precision blanks each consist of a layer of Divinycell buoyancy foam sandwiched between two aluminium plates. The design ensures that the closures have almost neutral buoyancy and can be easily handled under water by an individual diver. Unlike the majority of hull closures designed and built by Miko, the N’Kossa blanks will not be fastened by magnets. In this case Miko has manufactured interface units that are permanently attached to the hull and replace some unsuitable gratings over the inlets. Once the blank has been manoeuvred into position the diver turns a mechanical latch which clamps it securely in place. A two stage Celleprene parallel gasket then ensures a water-tight closure and enables maintenance work to be conducted safely inside the pipes.

Miko Marine AS is based in Oslo, Norway, from where it also provides a range of unique salvage and support products for the marine industry. Most widely known is its range of magnetic plasters which can be used to seal hull damage and enable a vessel to be moved safely to a yard for permanent repair. The company’s most recent innovation has been the Moskito oil recovery tool that was recently introduced as the first device that can enable bunker fuels and other hydrocarbon cargoes to be quickly and easily extracted from the tanks of sunken vessels.