The patent application for the Moskito – a compact and versatile tool for quick and safe oil removal from sunken vessels – has been approved by the Norwegian Industrial Property Office. The approval marks a major milestone during the final stage of the Moskito’s development.

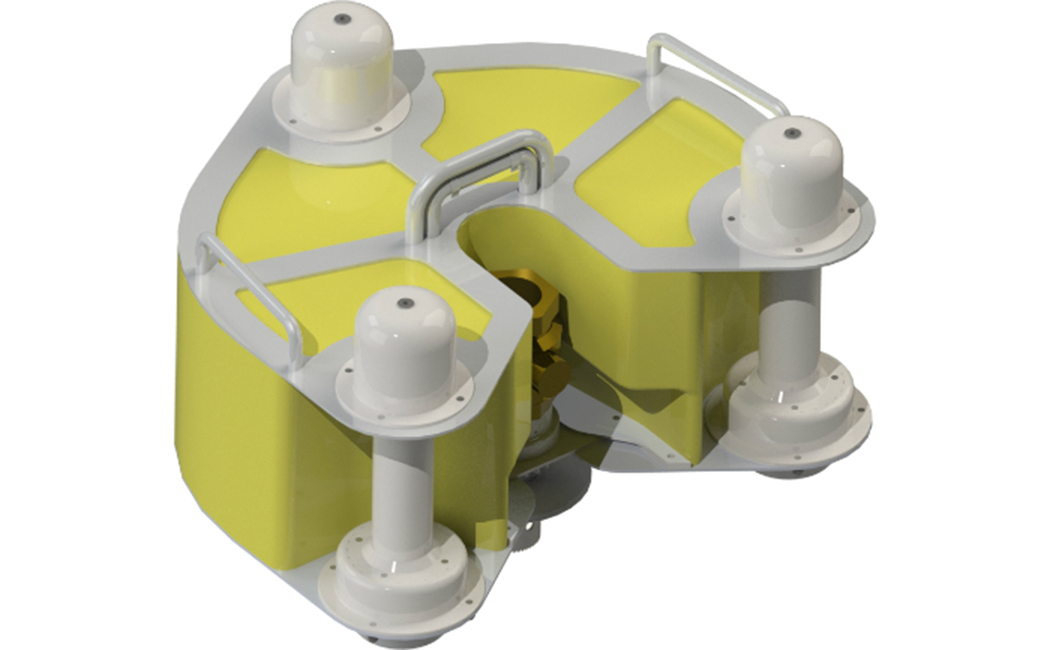

The concept is based on an electromagnetic tripod that enables the tool to be secured to the shell plate in a quick and safe manner. This is a major advantage compared with traditional methods using screw taps or welding. The tool can be secured to flat or curved surfaces without any modifications and no penetration or hot work is required.

By integrating the hole saw and valve into one piece, the processes of drilling a drain hole and then attaching the valve is merged into one step. This reduces the time and the complexity of the operation, while the amount of leakage during the process is reduced to a bare minimum. Once the hole saw has penetrated the hull, the machine can be detached. The hole saw is then left secured to the shell plating without leakage.

The hole saw is connected to a valve and can now be used either to pump the oil to the surface or to allow sea water to flow into the tank at the bottom. The Moskito, together with a number of hole saws, can be used for multiple operations to penetrate as many locations as necessary without resurfacing.

The complete oil removal tool, including hole saw, weighs around 70 kg, has a height of 500 mm and is neutrally buoyant in water. It can be handled by divers as well as ROVs and used in water down to 300 meters.