Teekay Shipping has ordered four sea chest blanks especially adapted for installation by ROV. Miko utilizes 3D laser scanning to measure the hull curvature. The closures will be delivered in August for use on the Gina Krog FSO on the Norwegian continental shelf.

The vessel is currently undergoing a USD $220 million conversion from the Randgrid shuttle tanker into the Gina Krog FSO (Floating Storage and Offloading) in Sembawang dockyard in Singapore. Conversion work includes the installation of an internal turret mooring system and on completion the new FSO will be operated by Teekay on Statoil’s Gina Krog field in the North Sea.

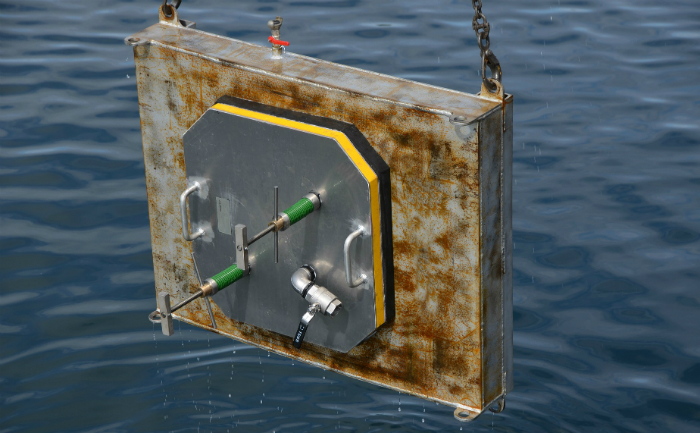

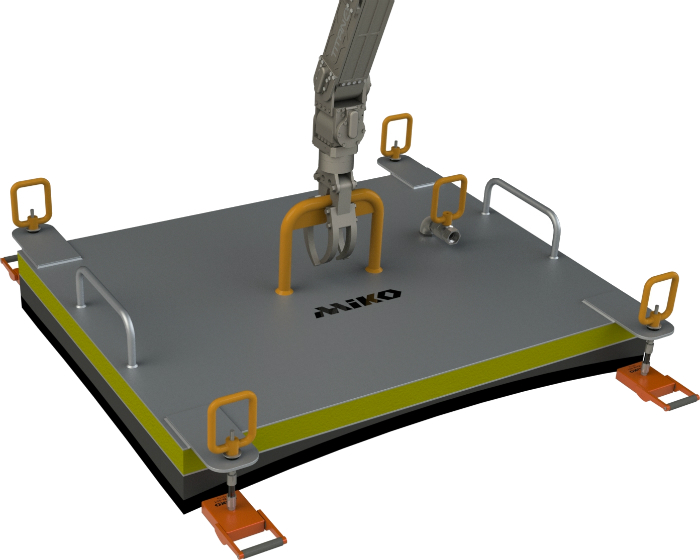

The precision manufacture of the blanks is being assured by Miko’s 3D laser scanning of the vessel’s hull contours. This was carried-out in the Sembawang dry dock in early March and the measurements are now being used as the basis for the blanks’ construction. The Miko closures to be will be based on designs recently supplied to Odfjell Drilling for use on its Deepsea Stavanger semi-submersible platform and they will provide safe and effective seals during work on sea chests .The blanks will each be fitted with powerful permanent magnets to permit fast and efficient positioning by ROVs (Remotely Operated Vehicles) and to enable their rapid recovery and storage for re-use.

Magnetic adhesion is the key element of the blanks’ design and Miko expertise in this specialised technology will enable significant time and cost savings to be achieved. The most notable application is the use of four powerful Miko MAM permanent magnets to hold each of the four blanks tight against the hull. With each magnet capable of holding up to 450 kg it is possible to achieve an instant watertight seal for the cofferdams without the need for any other attachments or holding mechanisms being fitted to the steel hull. Each magnet is connected to the blank via a special rubber link which introduces an element of flexibility that enables it to be fitted flush onto the hull while allowing the coffer dam to be positioned precisely before it is tightened into place. When the job is finished each magnet is simply freed by having its release lever lifted by a diver or ROV so the blank can then be retrieved.