The first magnetic blanking set destined for the Brazilian offshore sector has left the Miko Marine fabrication plant in Haugesund, Norway. After six weeks of manufacture, the set is now en route to the DSIC yard in Dalian, China. It will then be installed aboard a new Floating Production Storage and Offloading (FPSO) vessel being completed by Japanese platform builder MODEC. On leaving Dalian the new FPSO will be moved to the Bacalhau field offshore Brazil where it will be operated by Equinor.

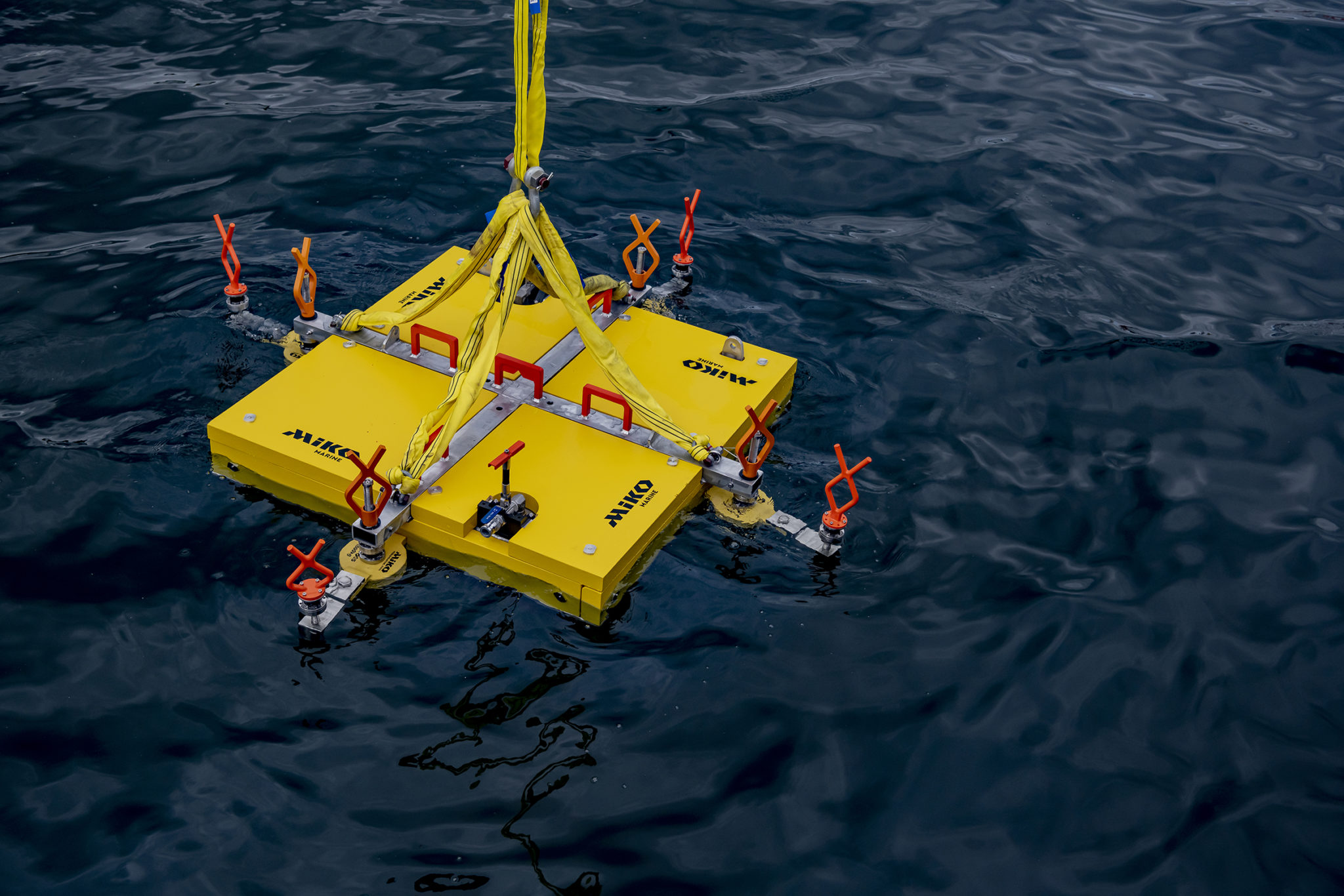

The new blanking set consists of four cofferdams that can be used for covering sea chests and three inlet pipe covers. Featuring Miko’s distinctive yellow trade mark colour scheme, their unique magnetic attachment system enables them to be quickly fitted over a hull opening by divers or ROV. They create an immediate water-tight seal without the need for any welding or hull attachments and can be quickly removed for recovery and storage until needed again. The ability to enable repairs and maintenance to be conducted without dry docking is seen as a major cost benefit and necessity for rigs and platforms which can remain on-station throughout.

Cato Stoll, managing director of Miko Marine, believes the delivery operation marks the completion of an important contract for Miko. “This is the culmination of a great deal of hard work and the application of detailed expertise by the Miko design team,” he said. “The team’s specialised knowledge and experience ensures that the magnetic blanking set will function safely and reliably for many years to come. When the new FPSO is on station offshore Brazil it will possess an operational cost benefit that is unique among FPSOs in the region. By designing and manufacturing the blanking set while the FPSO was under construction provided us with many benefits in terms of convenience and ease of work. Nevertheless, we frequently provide the same service as a retro-fit for ships and platforms whose operators want to avoid the cost and complications of ad hoc blanking contracts,” he said.

Miko has developed considerable experience in the design and manufacture of hull closures and cofferdams and has particular expertise in the use of magnetic technology. Each cofferdam or pipe blank is kept in place by a configuration of powerful Miko MAM permanent magnets. With each magnet being capable of holding up to 2000 kg it is possible to achieve an immediate watertight seal for the closures without the need for any other fastening devices being fitted to the hull. Flotation material is integrated within the blanking plates and this makes them neutrally buoyant and easily handled under water by ROV. Each magnet is attached to its closure by a flexible joint which enables the plate to be manoeuvred and positioned precisely against the hull before it is tightened into place. When the repair work is finished the magnets are simply freed by having their release lever rotated by a diver or ROV, enabling the blank to be quickly retrieved by crane and stored on board.

O PRIMEIRO CONJUNTO DE BLANKING MAGNÉTICO DA MIKO PARA O SETOR OFFSHORE DO BRASIL JÁ ESTÁ A CAMINHO

O primeiro conjunto de blanking magnético destinado ao setor offshore brasileiro já saiu da fábrica da Miko Marine de Haugesund, na Noruega. Depois de seis semanas de fabricação, o conjunto agora está a caminho do estaleiro DSIC em Dalian, na China. Em seguida, será instalado a bordo de uma nova Unidade Flutuante de Armazenamento e Transferência (FPSO), sendo concluída pela construtora de plataformas japonesa MODEC. Ao sair de Dalian, a nova FPSO será levada ao campo de Bacalhau, no litoral do Brasil, onde será operada pela Equinor.

O novo conjunto de blanking é composto por quatro ensecadeiras que podem ser usadas para cobrir baús de mar e três tampas de tubos de entrada. Apresentando o esquema de cores da marca registrada amarela da Miko, seu exclusivo sistema de fixação magnética permite que elas sejam instaladas rapidamente em uma abertura do casco por mergulhadores ou ROV. Elas criam uma vedação estanque imediata sem a necessidade de soldagem ou acessórios de casco e podem ser removidas rapidamente para recuperação e armazenamento até serem necessárias novamente. A capacidade de permitir que sejam realizados reparos e manutenção sem docagem a seco é vista como uma excelente relação custo-benefício e uma necessidade para sondas e plataformas que podem permanecer na estação o tempo todo.

Cato Stoll, diretor administrativo da Miko Marine, acredita que a operação de entrega marca a conclusão de um contrato importante para a Miko. “É o ápice de muito trabalho árduo e da aplicação da expertise detalhada da equipe de design da Miko”, afirma. “O conhecimento e a experiência especializada da equipe garantem que o conjunto de blanking magnético funcionará com segurança e confiabilidade durante muitos anos. Quando a nova FPSO estiver na estação no litoral do Brasil, ela terá uma relação custo-benefício operacional única entre as FPSOs da região. O projeto e a fabricação do conjunto de blanking, enquanto o FPSO estava em construção, proporcionaram muitas vantagens em termos de conveniência e facilidade de trabalho. No entanto, frequentemente prestamos o mesmo serviço como recondicionamento para navios e plataformas cujos operadores querem evitar o custo e as complicações de contratos de blanking ad hoc”, explica.

A Miko desenvolveu uma experiência considerável no projeto e fabricação de tampas de casco e ensecadeiras, com uma expertise especial no uso de tecnologia magnética. Cada ensecadeira ou tubo blank é mantido no lugar por uma configuração de ímãs potentes e permanentes MAM da Miko. Sendo cada ímã capaz de suportar até 2.000 kg, é possível obter uma vedação estanque imediata para as tampas sem a necessidade de instalar outros dispositivos de fixação no casco. O material de flutuação é integrado dentro das placas de blanking e isso as torna flutuantes de forma neutra, facilmente manuseadas sob a água por um ROV. Cada ímã é fixado à respectiva tampa por uma junta flexível permitindo que a placa seja manobrada e posicionada com precisão contra o casco antes de ser apertada no lugar. Quando o trabalho de reparo é concluído, os ímãs são simplesmente liberados com o giro da alavanca de liberação correspondente realizado por um mergulhador ou ROV, possibilitando que o blank seja rapidamente recuperado pelo guindaste e armazenado a bordo.